Tungsten Carbide (TC) Rings

Tungsten Carbide (TC) Rings are engineered for extreme durability and precision in high-speed rolling mills being the ideal choice for demanding rolling mill operations. In modern rolling mills, Tungsten Carbide (TC) Rings have emerged as a game-changer in the industry due to their exceptional wear resistance, extended lifespan, and superior performance. Whether in High speed wire and bar mills, TC rings help optimize production while reducing maintenance costs.

TC Rings are composed of tungsten carbide (WC) and cobalt (Co), nickel (Ni), chromium(Cr) binders, these rings offer superior resistance to abrasion, deformation, and thermal fatigue, making them ideal for demanding rolling mill applications. Tungsten (W) is a critical element in the manufacturing of Tungsten Carbide (WC) Rings, providing exceptional hardness, wear resistance, and thermal stability. As one of the hardest and most durable metals, tungsten plays a crucial role in high-performance rolling mill applications, ensuring long-lasting and reliable operation. While binder (Co- Ni- Cr) is the metallic phase that holds tungsten carbide (WC) grains together, giving the material toughness and flexibility while maintaining its hardness and wear resistance. The choice of binder significantly affects the mechanical properties, thermal stability, and corrosion resistance of TC Rings.

The Benefits of Tungsten Carbide (TC) Rings in Rolling Mills

- High Hardness & Wear Resistance – Extends roll life and reduces downtime.

- Superior Surface Finish – Improves product quality in rolling mills.

- Heat & Corrosion Resistance – Suitable for high-temperature and aggressive environments.

- Dimensional Stability – Ensures precise rolling with minimal deformation.

- Cost-Effective Solution – Reduces operational costs and improves productivity.

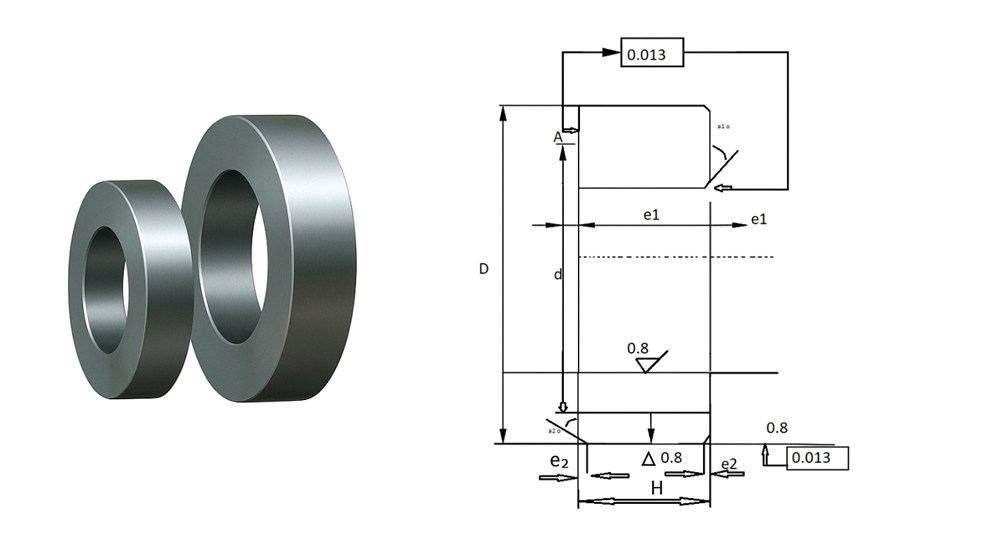

Dimensions of Finished Tungsten Carbide (TC) Roll Rings

1. Range of Dimensions of Finished Roll Rings:-

The dimensions of TC Roll Rings vary depending on their application and rolling mill type. Below are the typical size ranges:

| Parameter | Standard Range | Customizable |

|---|---|---|

| Outer Diameter (OD) | 100 mm – 480 mm | Yes |

| Inner Diameter (ID) | 50 mm – 380 mm | Yes |

| Height (H) | 20 mm – 200 mm | Yes |

2. Tolerance Levels allowable for Roll Rings:-

| Parameter | (D) ≤ 200 mm | (D) ≤ 200 mm | ||

|---|---|---|---|---|

| Standard Precision | High Precision | Standard Precision | High Precision | |

| Outer Diameter (OD) | ±0.02 mm | ±0.05 mm | ±0.03 mm | ±0.05 mm |

| Inner Diameter (ID) | ±0.0200 mm | ±0.0350 mm | ±0.0250 mm | ±0.0500 mm |

| Height (H) | ±0.025 mm | ±0.10 mm | ±0.05 mm | ±0.10 mm |

We can supply Tungsten Carbide Rings as per customer-provided drawings and specifications, ensuring precision and high-quality manufacturing.

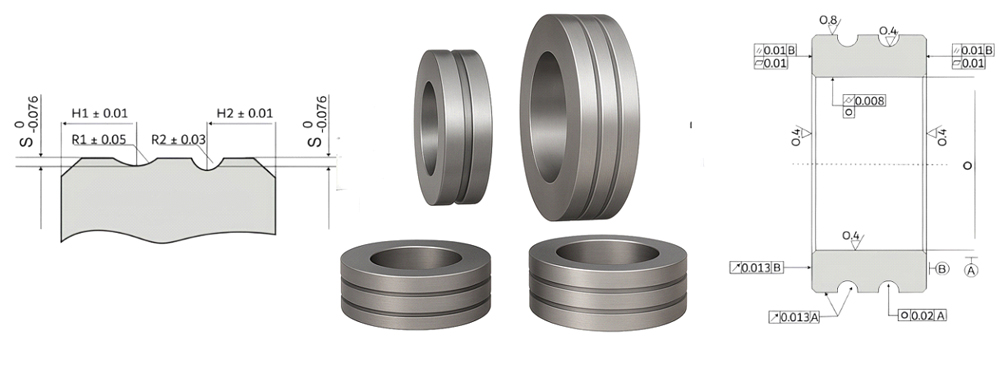

3. Advanced Science for High Precision:-

To achieve tight tolerances and optimal dimensions, TC Roll Rings undergo:

- Precision Grinding & Lapping – Achieves smooth surface finish and accurate dimensions.

- CNC Machining – Ensures uniformity and minimal dimensional deviations.

- Ultrasonic & X-ray Testing – Detects internal flaws for quality assurance.

- Hardness & Wear Resistance Testing – Ensures the required hardness level(HRA).

4. Technical Specifications of Finished Tungsten Carbide Roll Rings:-

Tungsten Carbide Roll Rings are manufactured with tight tolerances to ensure dimensional accuracy, high performance, and long service life in rolling mills. The allowable deviations depend on factors such as outer diameter (OD), inner diameter (ID), Height (H), and roundness.

5. Standard Allowable Deviations for Tungsten Carbide Roll Rings:-

| Parameter | Deviation |

|---|---|

| Radial runout of Groove | ≤0.013 mm |

| Radial runout of periphery | ≤0.013 mm |

| End face Runout | ≤0.02 mm |

| End face planeness | ≤0.01 mm |

| End face parrallelism | ≤0.01 mm |

| Inner hole cylindericity | ≤0.01 mm |

6. Roughness of Carbide Rolls

| Application | Roughness |

|---|---|

| Inner hole roughness | 0.4 m |

| Periphery roughness | 0.4 – 0.8 m |

| End face roughness | 0.04 m |

Tungsten Carbide (TC) Roll Rings – Grades & Specifications

At Vij Metals India LLP, we offer a range of Tungsten Carbide Grades to suit different rolling mill applications, ensuring high hardness, wear resistance, and superior rolling performance.

| Grade | Wc( %) | Binder Composition(%) (Co/Ni/Cr) | G/cm3 | ≥HRA | ≥N/mm2 |

|---|---|---|---|---|---|

| AV-08S | 92 | 8 | 14.7±0.15 | 88 | 2800 |

| AV-10S | 90 | 10 | 14.5±0.15 | 87.5 | 2750 |

| AV-12S | 88 | 12 | 14.2±0.15 | 86 | 2700 |

| AV-15S | 85 | 15 | 14.1±0.15 | 85 | 2650 |

| AV-18S | 82 | 18 | 13.7±0.15 | 83.5 | 2600 |

| AV-20S | 80 | 20 | 13.5±0.15 | 82.5 | 2550 |

| AV-25S | 75 | 25 | 13.1±0.15 | 80.5 | 2450 |

| AV-30S | 70 | 30 | 12.7±0.15 | 79 | 2350 |

Customization Available: We provide custom WC-Co/Ni/Cr grades based on customer requirements and mill conditions