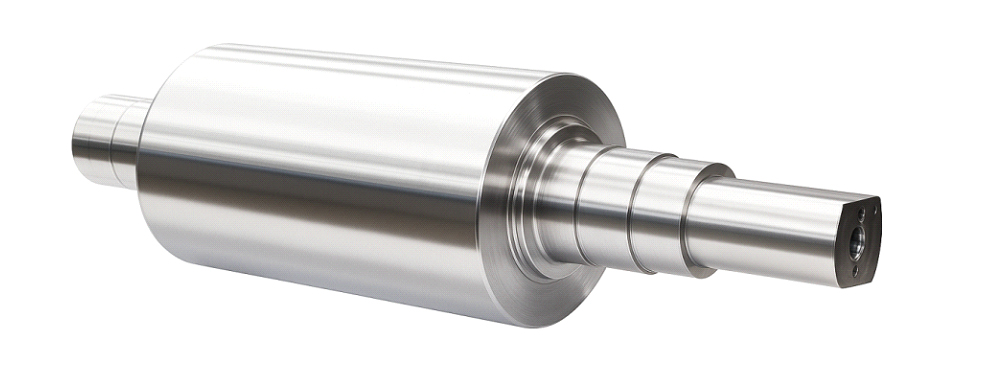

Adamite Rolls

Adamite Rolls are a special type of alloy cast steel roll, designed to combine the toughness of steel with the wear resistance of cast iron. These rolls are widely used in hot rolling mills, particularly in the roughing stands, where high mechanical strength and impact resistance are essential

Chemical Properties

Adamite is an alloy that typically contains carbon, chromium, nickel, molybdenum, and sometimes vanadium, forming a pearlitic or bainitic microstructure with finely dispersed carbides. This composition provides uniform hardness throughout the roll body, usually ranging between 35 to 50 HSD, which is a key advantage over traditional cast iron rolls that have varying hardness levels.

Due to their high thermal shock resistance, Adamite rolls perform exceptionally well under intense rolling temperatures and mechanical loads. They are also regrindable, allowing them to be reshaped and reused multiple times without losing their mechanical properties, which makes them highly cost-effective in the long run. These rolls are particularly suitable for rolling structural sections, bars, beams, wire rods, and billets, and they ensure a consistent rolling surface, enhanced dimensional stability, and longer service life under challenging rolling conditions.

Key Features

- Alloy Composition Made with a balanced blend of Carbon, Chromium, Nickel, and Molybdenum for enhanced toughness and wear resistance.

- Uniform Hardness Consistent hardness throughout the roll body (typically 35 – 50 HSD), ideal for deep grooves and extended roll life.

- Pearlitic/Bainitic Microstructure Offers a strong structure that balances durability with shock absorption.

- Excellent Thermal Shock Resistance Performs reliably under high temperatures during hot rolling.

- High Regrindability Allows for multiple regrinding cycles without compromising performance.

- Customizable Design Available in various diameters, lengths, and groove profiles to suit specific mill requirements.

Benefits of Adamite Rolls

- Reliable Performance in Roughing Stands Withstands heavy impact and mechanical stress, reducing downtime in early-stage rolling.

- Cost-Effective Solution More affordable than HSS rolls, while still offering long life and durability.

- Reduced Roll Changes Long wear life and deep machining capability reduce roll replacements and interruptions.

- Stable Rolling Process Maintains dimensional accuracy and consistent product quality across longer production cycles.

- Versatile Use Across Mills Ideal for section, bar, and wire rod mills in roughing and intermediate stands.