Guide Reels

Guide Reels ensure accurate alignment, proper metal flow, and precision in rolling mill processes. Made from high-quality alloy steel or carbide, they provide smooth guiding and longevity.

Dimensions:-

| Size | Outer Diameter (mm) | Thickness / Length (mm) |

|---|---|---|

| Small | 80 – 180 | 320 – 760 |

| Medium | 200 – 380 | 620 – 1450 |

| Large | 400 – 680 | 1000– 2800 |

Key Features

- High Wear Resistance – Prolongs service life.

- Accurate Guiding – Ensures precision in rolling operations.

- Customizable Designs – Available in different sizes & materials.

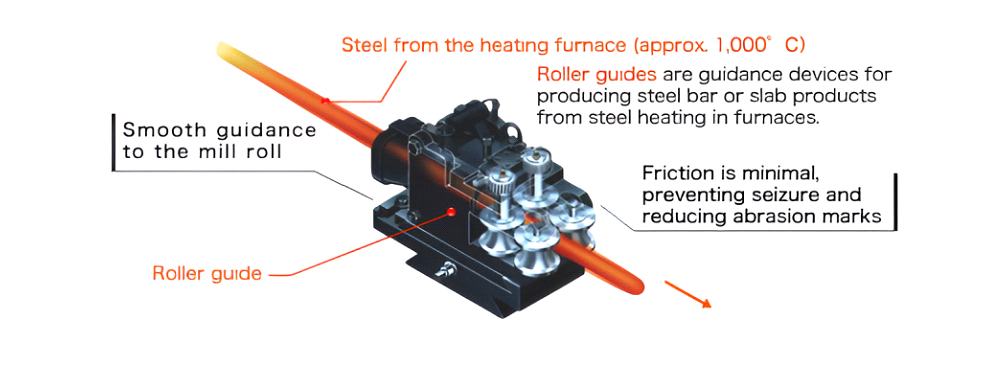

Working Principle

- Positioning the Material As the hot metal bar or rod approaches the roll pass, guide reels steer it into the correct position, ensuring that it enters the grooves accurately.

- Controlling Lateral Movement The rolls prevent side-to-side movement or twisting, which can lead to mis-rolling, poor tolerances, or groove damage.

- Maintaining Rolling Direction Guide reels ensure that the material stays in the intended rolling path, reducing the chance of deviation or erratic movement.

- Supporting Speed and Flow By keeping the metal stable, guide reels allow for faster rolling speeds, especially in high-speed continuous mills.